For your satisfaction and suggestions

İGÜMER

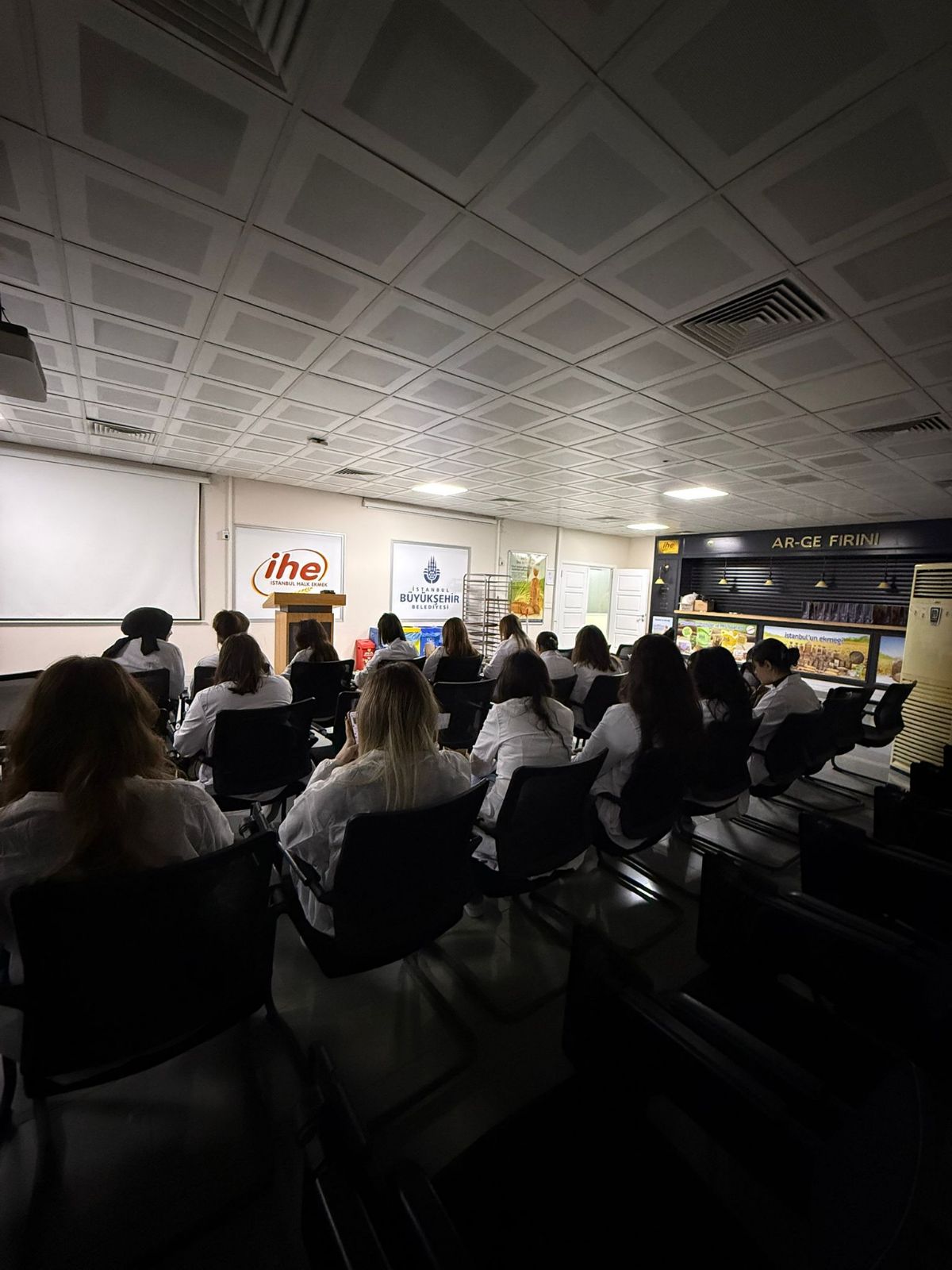

The factory team provided students with a comprehensive production line experience by presenting the bread-making process through a systematic flow from the initial stage to the final product. Key steps such as flour preparation, addition of dough ingredients, kneading, fermentation, resting, shaping, and baking were explained in detail along the production line.

Components specific to different product groups, temperature and time parameters, control points within the production flow, and how the factory’s hygiene–sanitation practices are integrated into the process were also described during the visit. In this way, students were able to observe not only the stages of production but also the essential role of quality assurance and standardization throughout the production line.

This visit also enabled students to link their observations with the topics covered in the course. Fundamental concepts such as the management of fermentation, processes that contribute to dough structure formation, moisture evaporation during baking, and the development of the gluten network were evaluated within a framework that allowed learners to mentally connect theory with real industrial practice. Thus, students had the opportunity to better understand how their theoretical knowledge is applied in an industrial production environment.

We extend our thanks to the Istanbul Public Bread team for their support of the technical visit, and to our students for their active participation, which contributed to a productive learning experience.

© Copyright 2022 Istanbul Gelisim University All Rights Reserved.